Ensuring WAIRE Compliance Across Warehouses and Fleets

As California advances its climate and clean air goals, warehouses in the South Coast Air Quality Management District (SCAQMD) are subject to regulatory requirements under WAIRE.

What is WAIRE?

WAIRE stands for Warehouse Actions and Investments to Reduce Emissions. The SCAQMD in California enacted this indirect source rule to reduce transportation emissions associated with warehouse operations.

Warehouse operators of facilities with an interior floor area of 100,000 square feet or more in the SCAQMD must comply with the WAIRE program (Rule 2305). This applies even if a portion of their facility is used for storage, or if the operator occupies at least 50,000 square feet of that area.

SCAQMD covers Orange County and parts of Los Angeles, Riverside and San Bernardino.

Regulation Overview

WAIRE is a truck traffic-based credit and deficit system impacting Class 2B through Class 8 trucks. Facility operators are required to monitor and submit real vehicle travel data from trucks entering and exiting the facility.

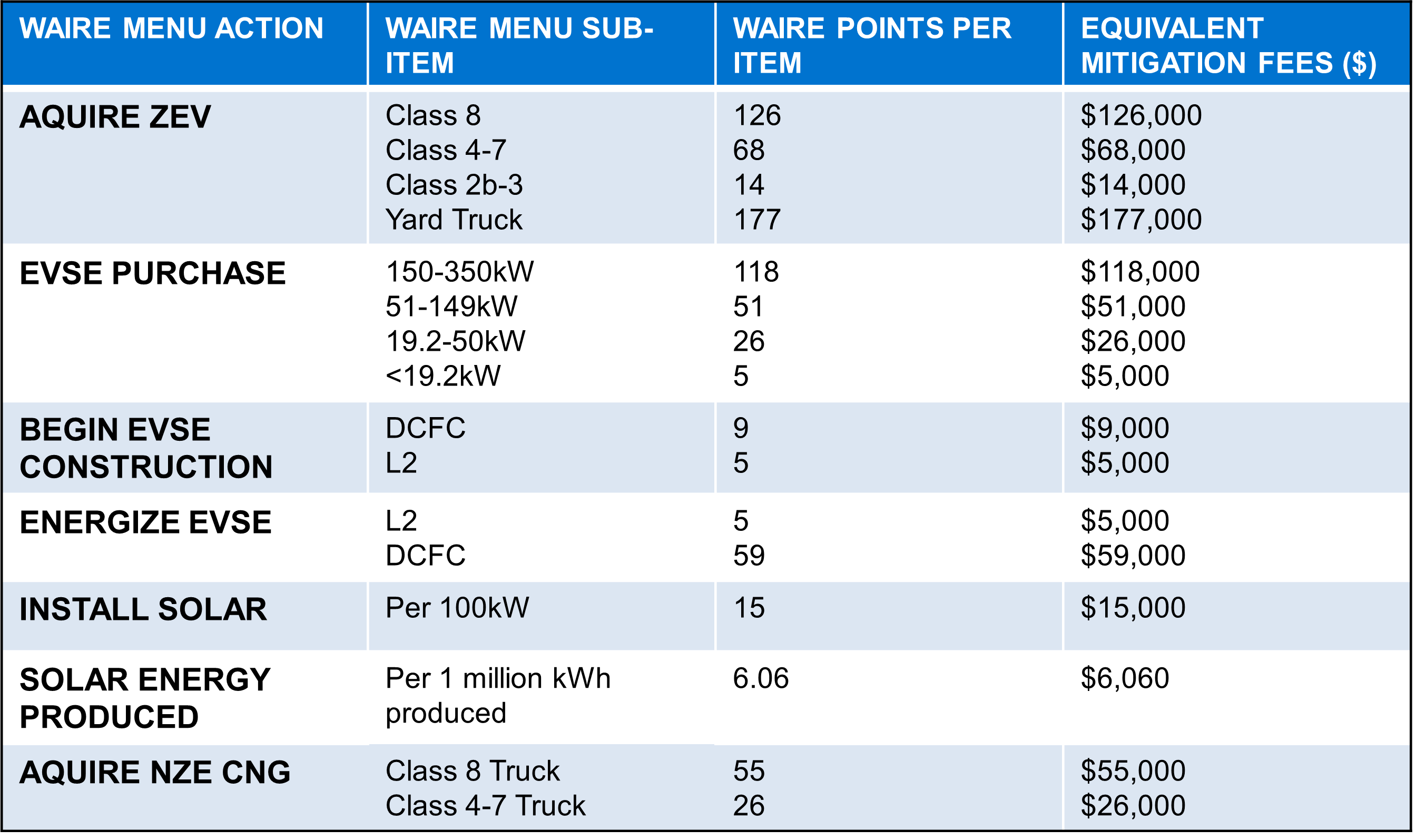

A facility’s WAIRE Points Compliance Obligations (WPCO) are totaled during preparation of the Annual WAIRE Report (AWR). It must then be offset by implementing mitigation activities from the WAIRE menu to earn WAIRE Points equal to the facility’s WPCOs.

Compliance includes either paying mitigation fees or earning WAIRE Points from the WAIRE Menu. Some ways to offset points include, but are not limited to, deploying zero-emission vehicles, installing electric vehicle charging stations or installing solar energy generation systems. If WAIRE Points earned do not offset WPCOs, the warehouse operator may be required to pay a mitigation fee per WPCO.

ZEV - Zero Emission Vehicle, commonly a battery electric vehicle or a hydrogen fuel cell vehicle

EVSE - Electric Vehicle Supply Equipment, otherwise referred to as an EV charging station

DCFC - Direct Current Fast Charger, otherwise referred to as a Level 3 charging station

L2 - Level 2 charging station, otherwise referred to as an AC charging station

Latest Updates

SCAQMD has collected approximately $48 million in mitigation fees to date as a result of the WAIRE program. These funds will support a WAIRE program that will fund zero-emission projects in the region. The program is expected to include grants for public and private companies to reduce nitrogen oxide and diesel emissions tied to warehouse activity.

Potential project types include on-road trucks, yard trucks, infrastructure and locomotives, along with charging and fueling infrastructure. The program is currently under development and should be complete by the end of 2025. Funding will be offered on a first-come, first-served basis.

These efforts aim to meet federal air quality standards and improve public health, especially in communities located near warehouses in the SCAQMD region.

Solutions To Meet WAIRE Requirements

Penske Truck Leasing has extensive experience operating, supporting and maintaining alternative-fueled vehicle fleets and has a wide range of low- and zero-emission vehicles that can help warehouse operators or fleets serving facilities within SCAQMD.

Currently, thePenske Truck Leasing EV Evaluation Fleet includes vehicles such as the Freightliner eCascadia, Freightliner eM2, Volvo VNR electric tractor, International® eMV™ and the Ford E-Transit. Our yard tractors include options like the Orange EV e-Triever electric terminal truck, Kalmar Ottawa T2 EV, Tico Pro-Spotter and Terberg Taylor YT203 EV. We also have Orange EV yard tractors available for rent, specifically located in the SCAQMD market for WAIRE compliance.

Penske Truck Leasing, along with Penske Energy, can help operators evaluate their needs and operations to determine the best solutions. Yard tractors often present an ideal entry point for fleets looking to embrace battery electric vehicle (BEV) technology since they travel fewer miles and return to base at night. Light-duty last-mile routes also work well, while regional medium- and heavy-duty equipment can work with the right routes and charging opportunities. Penske has a network of heavy-duty, high-speed electric charging stations in California that enable fleets to charge along their routes.

One of the challenges under WAIRE can be collecting data on truck visits, vehicle classes and fuel type. Penske Truck Leasing provides detailed fleet records through its Fleet Insight portal, which can assist with record-keeping.

Additionally, Penske Energy can help operators focus on the infrastructure side of WAIRE compliance. One of the most effective ways to earn WAIRE Points is through the installation and use of charging or fueling infrastructure for zero-emission vehicles. Penske Energy can help design, install and operate EV charging systems. When developing infrastructure, operators need to consider EV charging speeds, electricity costs and long-term EV adoption plans.

Charging infrastructure places new demands on the grid, where Penske Energy can assist with energy management solutions, such as load management, battery storage integration, and, if needed, microgrids to ensure reliable and cost-effective charging is available. The initial investment in EVs and charging infrastructure can be substantial, but Penske Energy also helps operators find rebates, grants and credits that can help reduce the overall cost.

Learn More: For more information on WAIRE, please visit the WAIRE website.

To talk with Penske Truck Leasing about vehicles to meet WAIRE compliance goals, contact electric.trucks@penske.com.

To learn more about available solutions, visit the Penske Energy website or email inquiries@penskeenergy.com.