Truck Drivers' Trip Planning Guide: 7 Things To Know Before You Go

What’s the difference between a professional driver who always arrives on time and one who’s constantly running behind? Preparation. Careful trip planning helps you expect the unexpected so you can reach your destination safely and on time. It also gives you peace of mind. Plan the best trip possible by following these seven steps every day before you leave the lot.

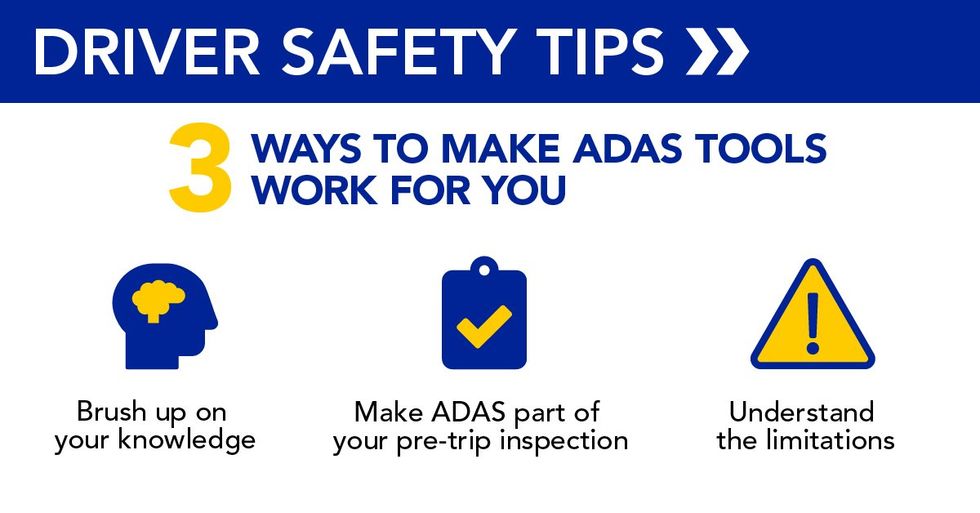

1. Perform Your Pre-Trip Inspection

Walk around your truck and trailer, looking for worn or damaged parts. Top off oil and coolant levels. Make sure lights and brakes are in good working order. Look for tire wear or rubbing and check the air pressure in all tires. Report any concerns to dispatch so they can be addressed quickly. Learn more about pre- and post-trip inspections.

2. Pack Your Paperwork

Roadside inspections can happen anywhere at any time. Prepare by carrying all essential documents, including your current CDL and DOT medical cards, Record of Duty Status, vehicle registration, proof of insurance, and shipping papers or bills of lading. If you cross state lines, make sure your truck sports an International Fuel Tax Agreement (IFTA) decal. Find out more about DOT and FMCSA requirements for rental trucks.

3. Set Your GPS

Map out your route using truck-specific GPS systems or apps, and ensure you know the weight and height of the vehicle you are operating. Check for any potential obstacles, such as low-clearance bridges, construction zones, weight-restricted roads or road closures. Set realistic drive times based on the roads you’ll travel and their speed limits, plan an alternate route in case you encounter any detours, and get to know these additional tips for avoiding dangerous situations on the road.

4. Plan Your Breaks

Identify the best places to eat, refuel and take your 30-minute breaks. On longer routes, book parking in advance so you have a safe, well-lit place to stay and sleep on your 10-hour break. How to find the best truck stops.

5. Check the Forecast and Monitor Traffic

Downpours, snowstorms and traffic jams can cause unexpected delays. Prepare by checking the weather before you leave and use your GPS to receive real-time traffic alerts.

6. Breakdowns Can Happen Anywhere

Pack a year-round emergency kit with a flashlight, emergency triangles, flares, reflective vests, tools, and non-perishable food and water. Add a shovel, ice scraper, snow brush, kitty litter and thermal blankets during cold-weather months. Carry extra water, portable fans, sunshades and cooling towels during hot-weather months. And always carry a fully charged fire extinguisher in your cab. Also, routinely inspect these items to confirm they have not expired and are working as they should. What to pack in a roadside emergency kit.

7. Expect Delays

Build extra time into your route to account for surprises — such as inspections, open weigh stations, and heavy traffic — so you don’t need to speed to reach your destination.

Common Questions

How do I plan a trip as a truck driver?

7 truck driver trip plannings tips are:

1. Perform your pre-trip inspection to ensure your vehicle is ready to go.

2. Pack your paperwork to be prepared for potential roadside inspections.

3. Set your GPS for your destination, ensuring the height and weight of your vehicle is taken into consideration.

4. Plan your breaks to stay hydrated, fed and well-rested.

5. Check the forecast and monitor traffic to steer clear of avoidable delays.

6. Breakdowns can happen anywhere so have a plan in place and keep an emergency kit in your vehicle.

7. Expect delays and build extra time into your trip to account for surprises.

Does Google Maps have a semi-truck mode?

No, Google Maps does not have a semi-truck mode that accounts for truck specifications (like height, weight, etc.) or truck-specific road hazards and restrictions. Check out the Best Apps for Truck Drivers to find apps made specifically for truck drivers.

How do I figure out a truck route?

Planning a truck route requires a variety of things, including reliable truck-specific technology, a routinely inspected vehicle, a well-rested driver and extra time built in to account for potential delays or on-road surprises.